Industrial Factory Warehouse Fluent Trip Structure Gravity Carton Flow Racking Easy to Assemble with Open Options

Description

Basic Info.

| Mobility | Adjustable |

| Height | 0-5m |

| Weight | 150-500kg |

| Closed | Open |

| Development | Conventional |

| Serviceability | Common Use |

| Color | Ral System |

| Thickness | 1.2-2.0mm |

| Surface Treatment | Powder,Galvanized |

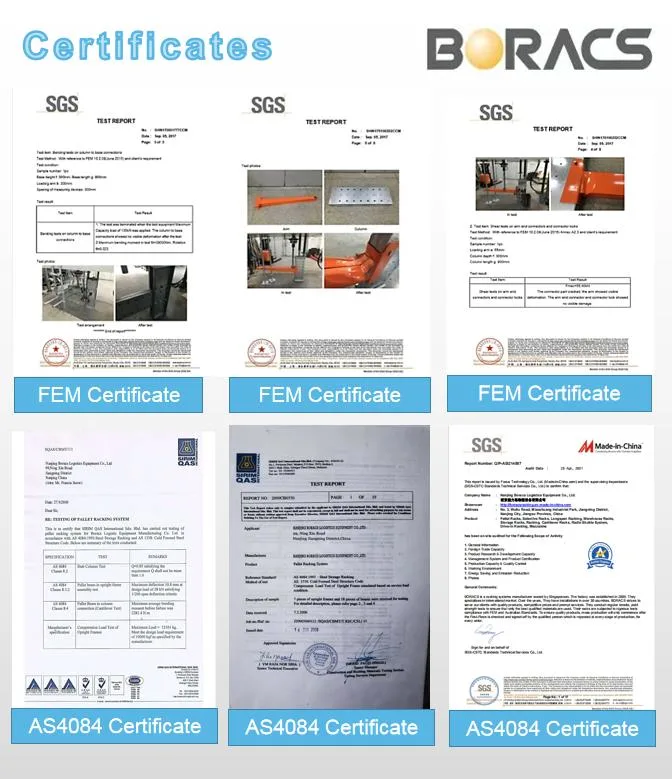

| Certificate | As4084,Fem |

| Transport Package | Standard Export Package |

| Specification | Customized |

| Trademark | Boracs |

| Origin | China |

| HS Code | 73089000 |

Product Description

Flow Through Rack/Flow Racking/Storage RackProduct Description

Carton flow rack improve visibility and order accuracy with its tilted shelves, it is the perfect answer for split case or piece picking. The racking is developed from the medium duty racking. Aluminum or steel roller rail are equipped between a pair of beams per layer to form a slope of 3 degree, and under the driven of gravity, product moved from the loading side to the picking side of the rack, "first in first out" of goods are realized. The height of the racking is normally lower than 2.5M and the loading capacity of each layer is 1000kg at the most. Shelves can also be adjusted to meet your picking height requirements.

Detailed Photos

Features:a) Unique aluminium or steel roller rail system which cartons move smoothly to the other side;b) FIFO( first in first out) realizedc) Flexible design on size and structure according to box or carton size;d) Dramatically improve warehouse efficiencye) Keep labor cost downf) Convenient access for two sides of assembly lineg) Perfect for warehouse slit case or piece picking

| Model | Pallet flow rack/Carton flow/gravity rack | ||||||

| Pallet Size | A) W1200*D1000mm | B)W1200*D1200mm | C) W1200*D1100mm | D) W1200*D800mm | |||

| Materials Optional | A) Quality Steel Q235A used for normal temperature storage situation | ||||||

| B) Quality Steel Q235B used for cold storage room | |||||||

| C) Environmental protection powder for surface treatment--powder coating | |||||||

| Craft-work | A) hole-punching | B) cold rolling | C) welding | D) powder coating | |||

| Structure | A) bolted structure | B) welded structure | |||||

| Color | A) as to our standard model | B) according to customer's requests | |||||

| Pack model | A) standard export packing | B) according to customer's requests | |||||

| Package material | A) transparent and dust-proof poly-sheet | ||||||

| B) hard carton paper | |||||||

| C) long and thin plywood bar | |||||||

| D) plywood pallet; steel and plastic straps | |||||||

| E) air bag used when loading container | |||||||

| MOQ | 5-10 sets; the model is subject to your requirements | ||||||

| Payment | A) T/T | B) LC | C) Paypal or Western Union | ||||

| Warranty | A) one year against manufacturing defect | ||||||

| B) 8-10 years of life time, offer lifetime consultation on problems occurred | |||||||

| Quantity | A) 20' container | B) 40' container | C) a sample order | ||||

| 17500kgs | 26000kgs | 1 set | |||||

| Delivery time | In 15 days | In 20 days | In 7 days | ||||

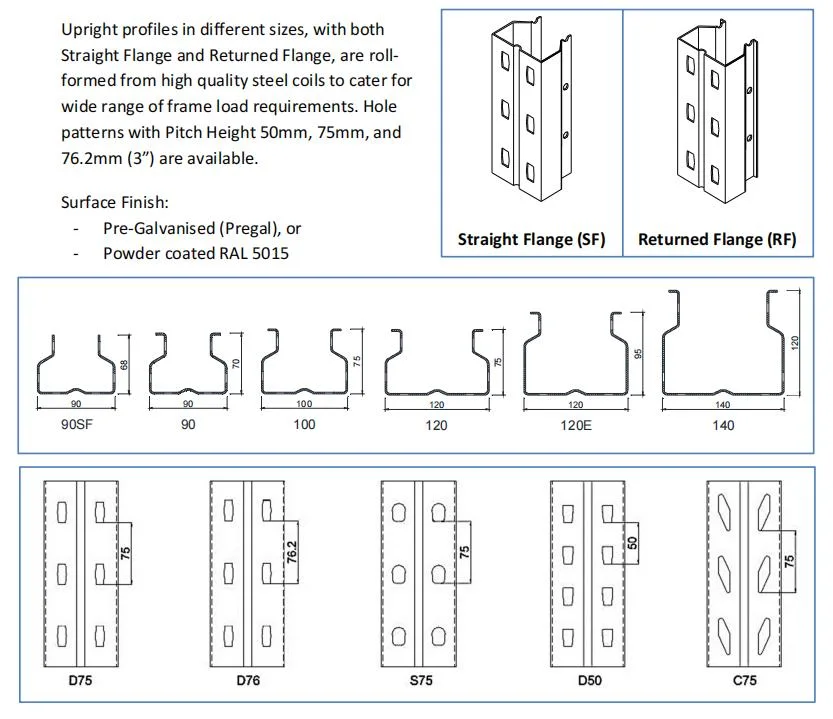

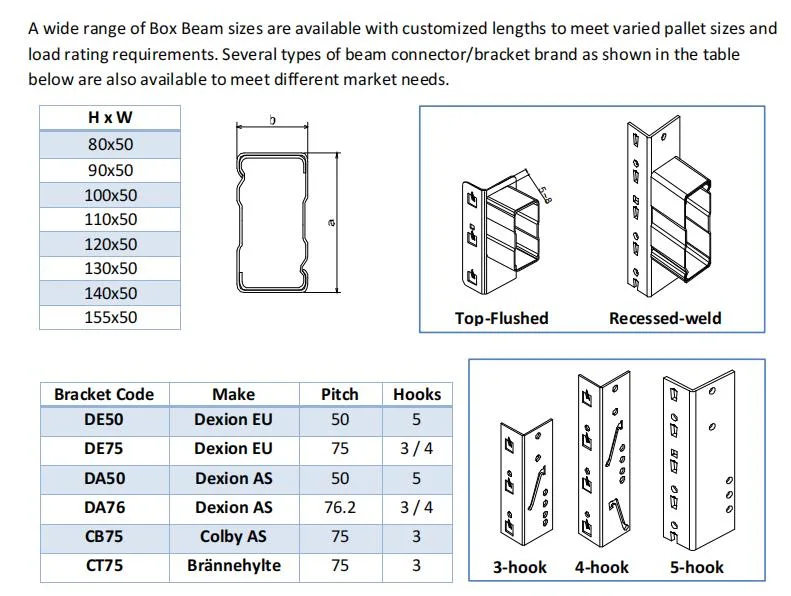

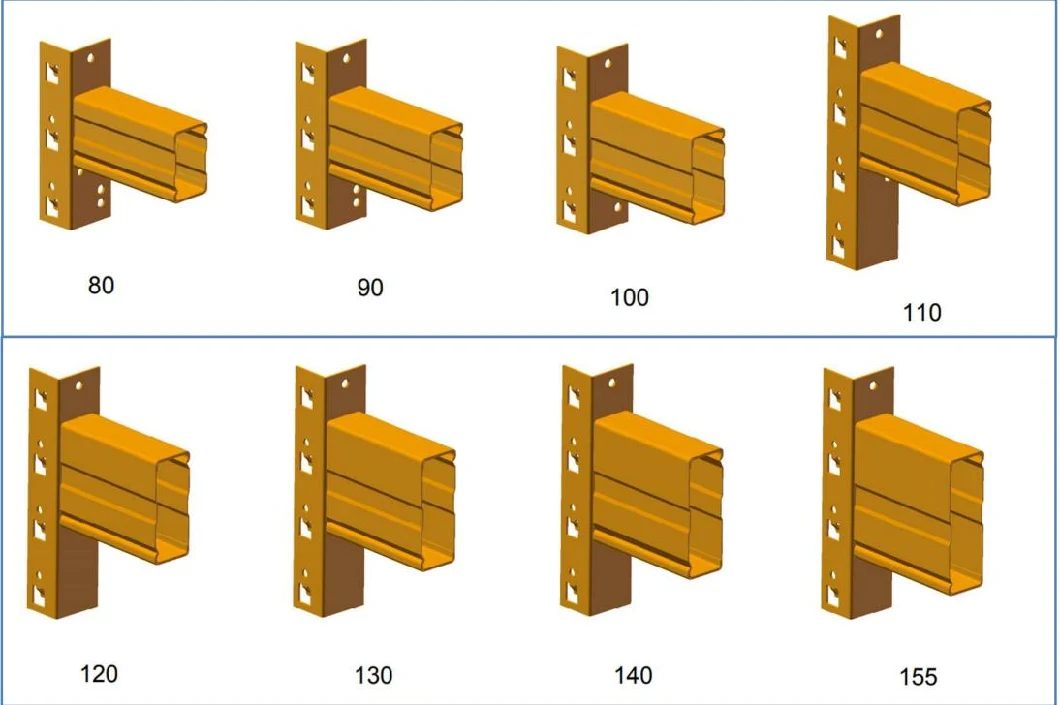

Upright:

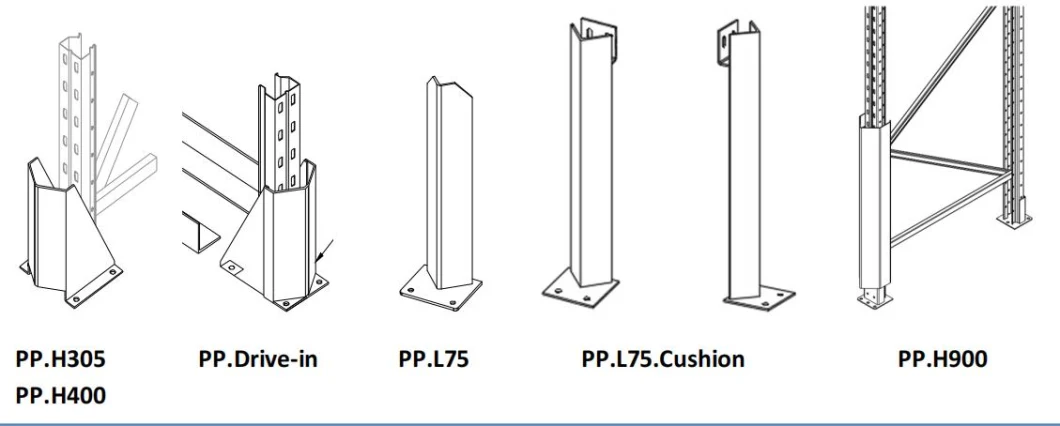

Upright Protector:

The basic essential factor for designing of heavy duty pallet racking and warehouse:First, cargo and pallet:1. Cargo weight (including pallet or steel box pallet).2. the size of pallet and cargo.3. the direction as the fork lifter enters the pallet to deposit and withdrawal cargo.Second, forks lifter:* model or technical parameter of Forklift.* biggest height of lift and the shortest distance for the channel to be used of forklift.Third, warehouse:1. the plane size of warehouse.2. the only high can be used of warehouse.3. the direction and the request as cargo enter the storehouse.

Company Profile

BORACS is a racking systems manufacturer 100% owned by Singaporean. Our China factory was established in 2004 in Shanghai and moved to Nanjing in 2009. BORACS specialises in international export market. Over the years, we have installations in over 30 countries, some of them shipped to end customers' warehouse, mostly are installed by our resellers around the world.BORACS strives to serve our clients and resellers with quality products, competitive prices and prompt services, thus keeping all our resellers onboard BORACS family since the first day they joined us. We conduct regular Tensile and Yield Strength tests to ensure that only the best qualified materials are used. Our Selective and Cantilever racks are subjected to rigorous tests compliance with European FEM and Australian Standards.

FAQ

Q: What's the trading terms?1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C is also available.2) Lead time: normally in 20-25 days after deposit received.3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.4) Shipping port: Shanghai / Nanjing China.5) Discounts: we offer good discount for large quantity

Q: How I can delivery my goods?1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items

Q: What is our service?1) Your inquiry related to our products or price will be replied in 12 hours.2) Well-trained and experienced staffs to answer all your inquiries in fluent English.3) OEM & ODM, any your customized racking we can help you to design product.4) We have very experienced professional engineers to make best solutions

Q: How to purchase our products?Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→ShippingQ: What's your advantage?1) Lead time: rush order we can fast delivery.2) Factory price: factory direct sale competitive price.3) Warranty: Two years warranty, the broken parts will be replaced and sent to you

Q: Does we have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products to fit at least one 20ft. container, which is about 15 tons.

Prev: Nova Walnut Living Room Furniture 48 Inch Open

Next: Customized Heavy Duty Powder Coating Stacking Tire Racks for Warehouse Open Frame Rack

Our Contact